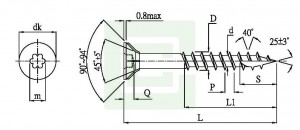

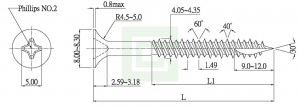

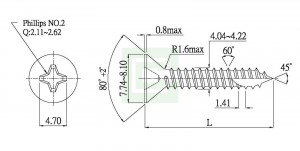

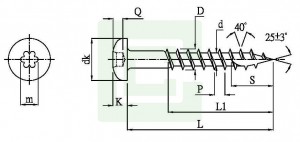

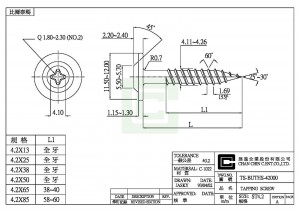

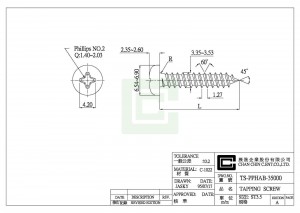

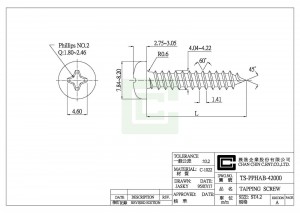

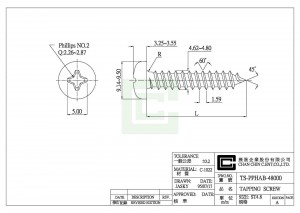

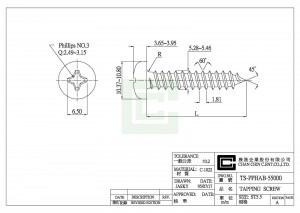

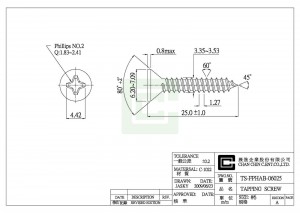

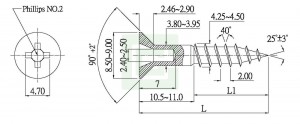

Self Tapping Screws

Self-tapping screws provide a useful and versatile range of fastenings. They are usually made from mild steel and, after the thread has been rolled, they are case-hardened to produce a hard surface at the thread with a tough core. Nickel or cadmium plating is the most common finish, but zinc, brass, copper and chromium platings are also used and plain steel and stainless steel screws are available.

There are two basic kinds of self-tapping screw: thread-forming and thread-cutting. Thread-forming Designed for use in materials which are softer than the screw material, this type forms or squeezes the material into which it is inserted to produce the internal thread. Thread-cutting As the name implies, this type cuts a thread in the material into which it is inserted. It can be identified by a flute which runs a short way back from the point along the side of the thread.

Clean Threading for Faster Assembly

Our OEM self‑tapping screws create secure threads directly into metal or plastics for efficient assembly.

Manufactured with controlled hardness and consistent tip geometry for dependable engagement.

Suitable for industrial, appliance, and general OEM applications requiring precise fastening.

.jpg?v=adde66f7)