Technology

Technology Information

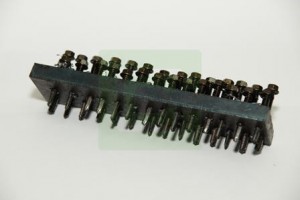

All completed items are made out of C-1022 material throguh several forming processes. We manufacture from the heading, threading and drill point forming, all are manufactured by our company and sent to the processing factory (heat treatment and surface treatment). Technical testing is provided before each delivery to ensure that our products are used perfectly without concerns.

Primary Competitive Advantages

- To serve customer better; we always provide stable and reliable products to achieve user freindly and make sure our products suit the customer needs.

QC

After the surface treatment, we run through several tests which include SDS Penetration Test, Salt Spray Test, Torsional Test and Tensile Strength Test. Once the products passed and approved by Q.C. The products will then packed and delivered to customers' hands.

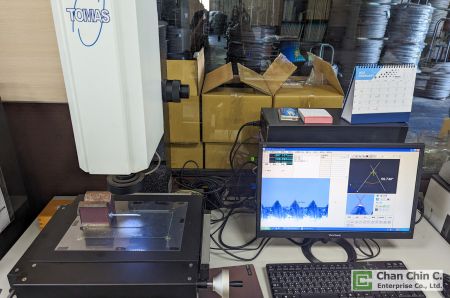

Q.C. Equipment:

- SDS Penetration Test

- SST Machine

- Torsional Testing

- Tensile Testing Machine

- Optimal Measurment Machine